In today’s rapidly evolving industrial landscape, hydraulic pump motors stand as the unsung heroes powering everything from construction equipment to manufacturing processes. These remarkable devices transform electrical energy into hydraulic power, creating the force necessary to move heavy loads with precision and reliability.

The Fundamental Mechanics Behind Hydraulic Excellence

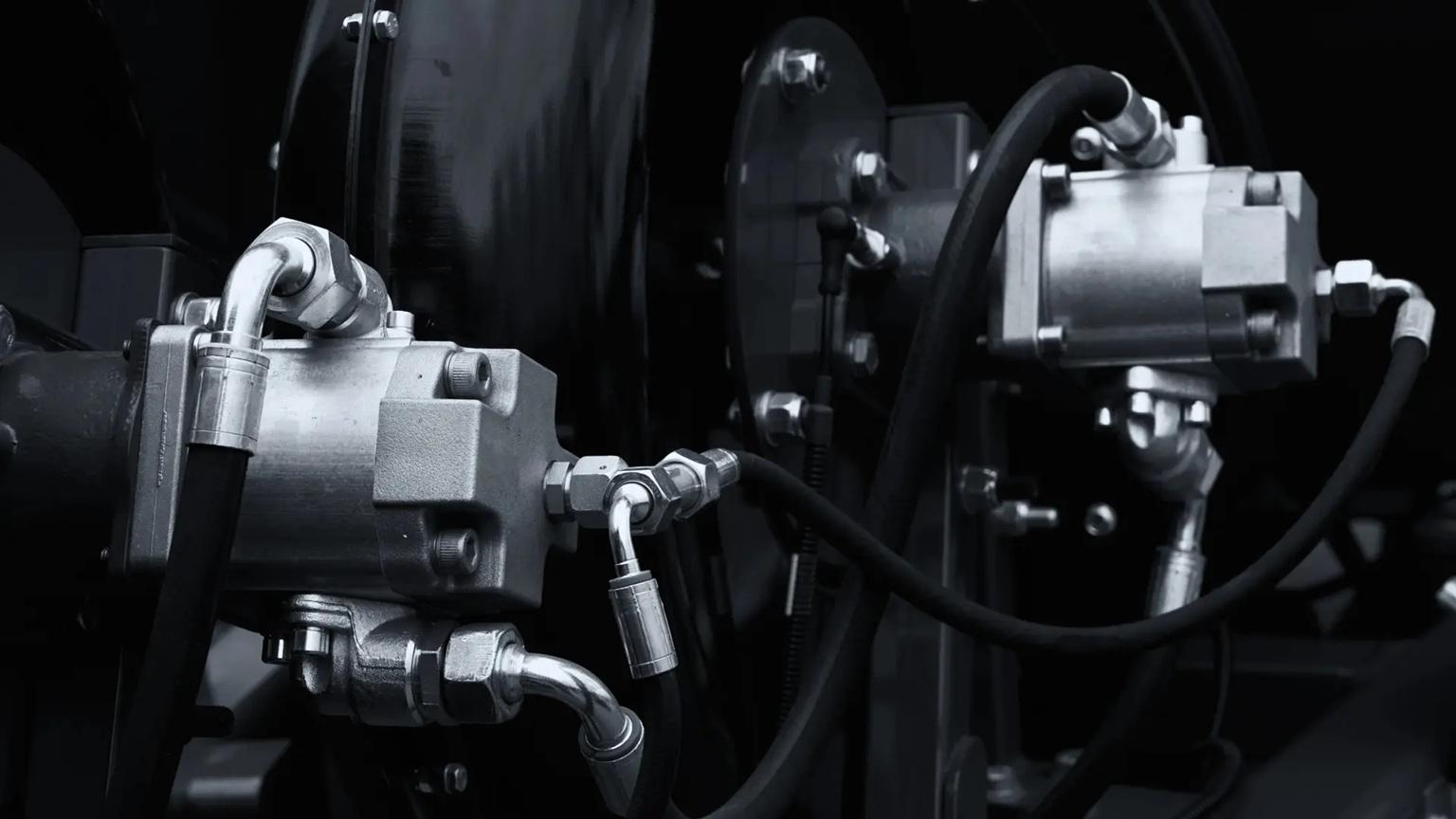

At its core, a hydraulic pump motor operates on a beautifully simple principle: it converts mechanical energy into fluid power. When activated, the motor drives the pump, which then pressurizes hydraulic fluid. This pressurized fluid becomes the lifeblood of the system, flowing through hoses and valves to actuators that convert this hydraulic energy back into mechanical movement.

The beauty of this system lies in its mechanical advantage. As Pascal’s principle demonstrates, pressure applied to a confined fluid transmits equally in all directions. This allows hydraulic systems to multiply force dramatically, enabling relatively small motors to generate tremendous power.

Types of Hydraulic Pump Motors: Finding Your Perfect Match

The diversity of hydraulic pump motors reflects their versatility across industries:

- Electric Motors: The most common type, offering clean, efficient operation with minimal maintenance

- Diesel Motors: Preferred for mobile applications where electrical power isn’t readily available

- Pneumatic Motors: Utilizing compressed air, ideal for explosive environments where electrical sparks pose dangers

- Petrol Motors: Offering high portability for remote locations and temporary installations

“The global hydraulic pump motor market is projected to reach $10.4 billion by 2026, growing at a CAGR of 4.2% from 2021 to 2026, driven primarily by infrastructure development and automation in manufacturing.” – Global Market Insights

The Technical Ballet: How Performance Parameters Define Success

Understanding the technical specifications of hydraulic pump motors reveals why selecting the right one is crucial for operational efficiency.

Displacement and Flow Rate

Displacement—measured in cubic centimetres per revolution—determines how much fluid the pump moves with each rotation. This directly affects the flow rate, which is the volume of fluid delivered per unit time (typically litres per minute). Higher flow rates enable faster actuator movement but require more power from the motor.

Pressure Capabilities

The pressure rating of a hydraulic pump motor system, measured in bars or PSI, defines its force-generating capability. Higher pressure ratings allow for greater force generation but demand more robust components throughout the system.

Efficiency Considerations

Modern hydraulic pump motors strive for maximum efficiency in three key areas:

- Volumetric Efficiency: The ratio of actual fluid delivered versus the theoretical displacement

- Mechanical Efficiency: How effectively the motor converts input power to output power

- Overall Efficiency: The combined effect of all efficiency factors, typically ranging from 80-92% in premium systems

Revolutionary Applications Across Industries

The versatility of hydraulic pump motors has made them indispensable across numerous sectors:

Construction and Infrastructure

From the massive excavators reshaping our landscapes to the precise positioning systems in bridge construction, hydraulic pump motors provide the controlled power that makes modern construction possible. Their ability to maintain force without continuous energy input makes them particularly valuable for holding heavy loads in position.

Manufacturing Excellence

In factory settings, hydraulic pump motors power everything from metal-forming presses to injection moulding machines. Their precise control capabilities allow for the creation of complex components with exacting tolerances.

Agricultural Innovation

Modern farming equipment relies heavily on hydraulic systems for functions ranging from steering assistance to implement control. The durability and power density of hydraulic pump motors make them ideal for the harsh conditions and variable loads encountered in agricultural applications.

The Future: Sustainability and Smart Technology

As industries worldwide embrace sustainability, hydraulic pump motor technology is evolving to meet new challenges:

- Energy-efficient designs that reduce power consumption

- Smart monitoring systems that predict maintenance needs

- Integration with IoT networks for remote operation and diagnosis

- Biodegradable hydraulic fluids that minimize environmental impact

Maintenance Wisdom: Extending Service Life

The longevity of hydraulic pump motors depends significantly on maintenance practices:

- Regular fluid analysis to detect contamination and degradation

- Temperature monitoring to prevent overheating

- Filtration system maintenance to protect sensitive components

- Alignment checks to minimize mechanical stress

“Proper maintenance can extend the service life of hydraulic pump motors by up to 300%, representing one of the highest ROI activities in industrial equipment management.” – Global Hydraulic Power Institute

Making the Right Selection: Factors to Consider

When selecting a hydraulic pump motor, engineers must carefully evaluate:

- Required flow rate and pressure for the application

- Duty cycle and expected operational duration

- Environmental conditions, including temperature extremes and exposure to elements

- Space constraints and mounting options

- Total cost of ownership, including energy consumption and maintenance

Conclusion: Powering Tomorrow’s Innovations

As we look to the future, the continual refinement of hydraulic pump motor technology promises even greater efficiency, control, and integration with digital systems. From construction sites to factory floors, these powerful components will continue to evolve, adapting to new challenges and opportunities. Whether powering massive earth-moving equipment or providing precise control in delicate manufacturing processes, the fundamental principles that make hydraulic systems so valuable remain unchanged—a testament to the enduring excellence of hydraulic pump motors technology.