Tool design, workstation design, and scheduling of tasks are key factors in the safe and risk-free use of hand tools. Prevention strategies should also be in place to address all these aspects.

What are The Major Ergonomic Concerns of a Hand Tool Design?

Weight of The Tool

Ideally, you should be able to use the tool in one hand. Tool weight may depend on the use:

- 2.3kg if the tool will be used away from the body or above the shoulders; and

- 0.4kf for precision tools that allow good control.

The center of gravity should be aligned with the center of the gripping hand. Tools should be easy to hold in an upright position or in the position where they will be used.

Handles

Handles and grips should be designed for power grip.

- Handle shape. Angled handles, or pistol grips, are useful when force is exerted in a horizontal straight line. Straight handles are for forces that are applied vertically. Shaped tools are effective when tasks are done at the same height as the arm and hand. Tools should not require wrist flexion, extension, or deviation. Your wrist should always be straight and in a neutral position. In other words, bend the tool, not the wrists.

- Diameter. In general, cylindrical handles at 40mm provide a better power grip and 12mm for precision grips. A larger diameter allows maximum torque, while a smaller one helps with dexterity and speed.

- Length. A handle should extend across the entire breadth of the palm. It should not be less than 100mm. A length of 120mm is recommended. Using gloves would require longer handles.

- The separation between handles. Pliers and tongs are equipped with two handles. The distance between the two should be around 65-90mm.

- Materials and texture. Friction must be present between the hand and the handle. Handle material should be non-slip, non-conductive, and compressible. Glossy coatings and highly polished handles are not recommended. They should be made of plastics or compound rubber.

Ergonomic factors that are unique to powered hand tools:

- Power tool triggers. This refers to the trigger finger (the index finger) and the trigger thumb. Frequent movements of the two fingers pose a risk for tendonitis. Using two or three fingers to activate the tool minimizes discomfort and the risk of injury.

- Vibration. Using anti-vibration materials in the design stage will lessen some vibration depending on the kind of material used.

Tips for better power tool ergonomics:

- Do not forcefully squeeze the handle of the power tool. This may cause fatigue in your hand and wrist muscles. Use just enough force to maintain grip and control.

- Avoid unnecessary force. Let the tool do its work.

- Use tool balancers to remove the weight of the tool if available.

- Use a handrest on the tool when pushing forward. This will allow you to use your larger shoulder muscles to generate more force.

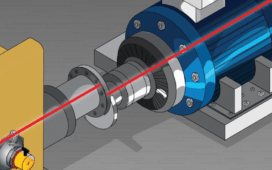

- Maintain a neutral wrist posture by using pistol-grip tools in a horizontal orientation. Straight tools should be used in a vertical orientation.

Suncoast Precision Tools is an official distributor of Williams Tools. Williams has created robust, trusted tools for industrial professionals with pride since 1882. You can check their collection here.