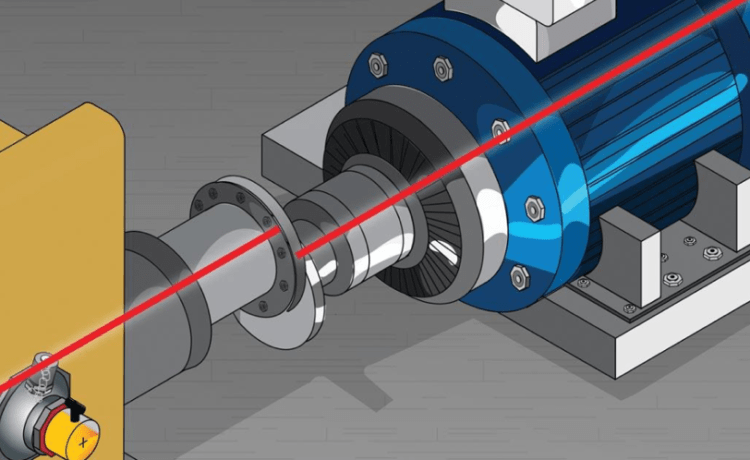

A laser alignment tool is a precision instrument used to align objects in two or three dimensions. It is commonly used in manufacturing, assembly, and inspection applications. Laser tools are available in a variety of sizes and designs and can be used with a variety of different objects.

This article will discuss how to use a laser alignment tool. We will cover everything from selecting the right laser alignment tool for your application to properly aligning objects using laser alignment.

Get the Right Robot:

The first thing you need to do when selecting an alignment tool is determining what type of robot you have or plan on using. This will help determine what kind of accessories you need for your application. For example, working with a six-axis robot arm, you will need an alignment tool with at least six degrees of freedom (DOF).

Consider your working environment:

When selecting a laser alignment tool for your working environment, several factors should be considered. For example, if you will be operating in an enclosed space (such as an industrial robot cell), then it may be necessary to choose a model with high-contrast optics so you can see the laser beam even under low-light conditions or through glass surfaces.

Select the right accessory or mount:

The first step in using a laser alignment is selecting the right accessory or mount for your application. Next, you will need to determine which mount will work best for your application and whether you need to purchase one or if you have one available. Adapters, mounts, clamps and other accessories are available from most laser manufacturers.

Adjust the lens:

Next, you must adjust the lens to align properly with your target object. This may involve adjusting a knob on the side of the device or moving a lever on top of it until your target appears sharp in a viewfinder or on the display screen. If you use an LCD screen instead of an optical viewfinder, you can also use this opportunity to calibrate it.

Adjust the laser beam focus:

Most alignment tools use a laser pointer to align objects. This is an important step because it allows you to see where the laser is pointing so that you can align objects with it. You will need to adjust the laser’s focus to be sharp and clear when using it for alignment purposes. The exact method for adjusting this varies between different types of lasers, but in most cases, a knob or dial on the side of the tool will allow you to adjust this setting.

Use a tripod if necessary:

Some lasers come with mounting hardware that can attach them directly to a tripod or other fixture. If your tool doesn’t have this built-in feature, consider purchasing it separately. This will allow you to use your laser while keeping both hands free, making it easier to track where your alignment object is located at all times.

Level the object you are aligning:

The most important step when using any laser alignment tool is ensuring that the aligned object is level. This ensures that the beam from the device will not reflect off an irregular surface, causing inaccurate readings. To ensure that an object is level, check both ends of it and make sure that they are parallel with each other and perpendicular concerning gravity.

Conclusion:

Now that you know how to use a laser alignment tool, you are ready to start. These tools are great for various applications, including manufacturing, assembly and inspection. You may also be interested in our guide on the best laser levels or finishing nailer reviews.